When we first opened our store, we offered alpaca socks that were made in Peru. This was a commonsense approach sense most of the world’s alpacas live in Peru and most alpaca socks originate from production plants within Peru.

A few years ago, we reworked our approach, and we began producing USA made alpaca socks that were made from USA grown alpaca fiber. This was a collaborative effort with other farms so we would have enough raw fiber to work within the USA’s textile industry. This was good for us, good for the sock buyers, but also great for the alpaca industry within the United States.

The first year of production was focused on our Michigander sock line. We were very happy with the product, and we’ve sold a ton of these socks to both retail and wholesale buyers.

Everything was great until it wasn’t.

When Things Starts to Fall Apart

Last year we worked on a new production run, and things started to unravel. Everything ran smooth for months, but then quickly became a disaster once we hit knitting. The company knitting our socks wasn’t following instructions, they would use the wrong materials, they’d mix the wrong colors, and they would over produce one size of socks while leaving us with nothing in another size. It was frustrating, expensive, and not workable long-term. Add in the fact that this process uses a natural product (raw alpaca fiber) that takes an entire year to grow made the failures only worse.

I was distraught, and I’ll admit, I was pretty darn angry. We’re a small, family-run alpaca farm that invested a lot of time, money, and emotion into this process and we were having nothing but issues. I’m not one that cries, but tears were flowing, and it was tears of disappointment and frustration. How could we invest so much of our lives into trying to create a solid, USA made product only to have one company ruin it all?

We made the tough decision to pull all our raw materials. There was no point continuing with a knitter that wouldn’t follow purchase orders and didn’t care about creating a quality product.

You’re probably wondering why we just didn’t move to a new company for knitting. We would have if they existed. The textile industry in the United States is a fraction of what it was decades ago. Most manufacturing capabilities have moved overseas, machinery is no longer available, and expertise no longer exists. There are few companies knitting socks in the USA and even fewer who are willing to work with smaller production runs or a natural product like alpaca. We researched these options, and we’d would hit a dead-end with each option we found.

Finding a Solution to an Industry Wide Problem

My husband Jason was the voice of reason. He had worked in the automotive industry for decades and he had spent most of this time moving back and forth between manufacturing plants and board rooms. For over a decade he missed anniversaries and holidays as he helped fix quality issues around the world, but this work came full circle and this experience finally paid off in ways we never expected. He knew the manufacturing process in and out and he was a specialist in quality control. He knew what we were experiencing wasn’t right and that there were other options.

He started to research opportunities for bringing knitting in house. And by in house I mean knitting on our alpaca farm. I’ll be honest in the fact that this scared me a lot. I did not know anything about manufacturing and the entire topic was intimidating. It was also super expensive.

Jason loves a challenge, and he wouldn’t let my dream of creating quality alpaca products die. He wanted to do good for the industry, our customers, and of course make me happy. It’s just the kind of guy he is – see the problem, diagnosis the source of the problem, and figure out a solution that works for everyone involved.

We searched and searched for equipment only to discover that there was little information available. And of course, this would be the case since little production equipment exists in the USA now that the textile industry is fragmented. What is left of the textile industry is a community of people that all know each other and know where to source what they need. We were outsiders and we were making limited progress.

We finally happened across a textile consulting company in North Carolina that could not only sell us a machine, but they could also help us design socks and provide onsite training. I remember the day I first called and had a chance to talk live to a real human. My comment – which produced a lot of laughter – was you are exactly what we’ve been looking for and I’m so happy I’ve found you. I meant every word of that statement.

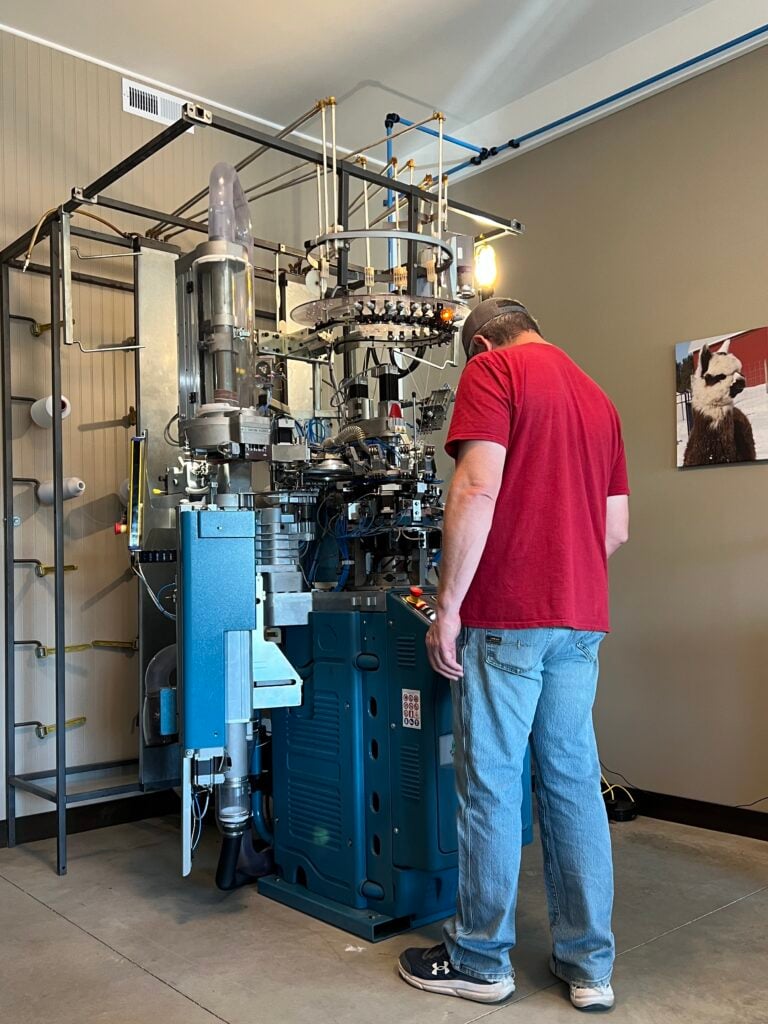

We shipped some of our sock yarn to the consulting team to create proof of concepts for us. This could demonstrate the proposed sock machine from Italy would work with alpaca and it could produce the styles we needed. After a few trials it was clear the Santoni sock machine had what we needed. I thought this was a massive milestone, but I didn’t realize it was just the start of a very long process.

To be able to accommodate this new machine we had to retrofit a lot of our farm and our existing storefront. New walls went up, doors were swapped out, existing electrical was rewired, new electrical was installed, and a bunch of equipment was purchased to help this new machine run. So many things needed to be done and so many expenses kept cropping up. The budget we had created just kept growing and growing.

We’re now about six months into the process. Our fancy HT-50 sock machine is here, we’ve had a week of on-site training, and we are finalizing sock styles and sizes. We’ve discovered the machine can create more styles than we thought and the quality far exceeds what we had when knitting was outsourced. The Italians know their knitting machines and Lonati has engineering down!

We’re now about six months into the process. Our fancy HT-50 sock machine is here, we’ve had a week of on-site training, and we are finalizing sock styles and sizes. We’ve discovered the machine can create more styles than we thought and the quality far exceeds what we had when knitting was outsourced. The Italians know their knitting machines and Lonati has engineering down!

It has been a journey to say the least. We’ve been reminded that you’re never too old to learn, and that doing the right thing often requires a longer and much more difficult path.

Both my husband and I know this purchase isn’t a smart one financially. It will take us forever to obtain payback on the machine if you look at the per sock cost to knit versus the quantity we will make and sell in the years to come. We know this and we moved ahead anyway because we know this route is good for our product buyers and the alpaca industry within the United States. Sometimes you have to look past yourselves and see the bigger picture.

The purchase of an industrial sock machine and this path have a greater purpose. It serves more than our farm and the people who buy socks from us.

Here is why:

- It demonstrates that textile manufacturing can work within the United States. It isn’t the easiest path, but it is a viable one.

- It will help move alpaca fiber out of barns throughout the United States. This is an issue for our industry since most farms struggle to convert their raw fiber into end use products for sale.

- It creates true USA made products. Many USA made alpaca socks are really USA knitted socks with Peruvian yarn. While the Peruvians are amazing people who create amazing goods, there is a lot of people who want locally made items.

- It is the definition of sustainability. It creates locally sourced and locally made products, which is good for our environment.

- It will help our alpaca industry grow and evolve into what we need to be successful long-term. Alpacas are cute and cuddly, but their true purpose is fiber. Alpacas are a livestock animal with a livestock business model, which means we must use these animals as intended. So many farms struggle with this right now.

- And our hope is to offer knitting to other farms within the US, so we can help convert their raw fiber into socks made from their animals. Will this make us a lot of money? Heck no. It will probably be more hassle than it is worth, but again, it is good for the industry, our fellow alpaca farmers, and the animals we all love. This means it is worth doing.

We make this journey not just for us, but also for our industry, our alpacas, and for the environment.

Jason and I have discussed this many times over the last year. What we are doing isn’t just about today or our farm. It’s about the future of the alpaca industry and making sure it has longevity so the next generation can experience these animals and the products they create.

Each Sock has a Story and We Want it to be a Great One

This video shows the final toe closure of an alpaca sock being made. The toe closure process takes only about a minute, but the entire knitting process takes about five minutes per sock. If everything is set up properly and goes without issue, the machine does all the work.

Let me just say, I will never look at my socks in the same way. The machine makes the process look so simple, but there are so many moving parts and so many things can go wrong. I again applaud the Italians and their craftsmanship in creating this machine.

Take a moment and look at the socks you’re currently wearing, then as yourself a few questions:

- Do you know what materials are in your socks? Most likely they are made from polyester which is made from petroleum. Let that sink in.

- Do you know how far your socks have traveled? Most likely they were made overseas in China, India, Pakistan, Turkey, or South Korea. Your socks have traveled a long way, and they’ve used up a lot of resources in the process.

- Do you know who made your socks? For 99.99% of the world, the answer is no. We have no idea who made the socks, what conditions they live in, what conditions they are forced to work in, or the age of the workers.

But we can do better. And we’re trying really hard to do so.

Let’s now look at the process for making alpaca socks. As we produce our new socks, we are making sure we do everything we can to stay local and remain fully traceable.

Before our alpaca socks are available for sale, they take a journey:

- The alpacas will grow their fiber for an entire year.

- The shearing team arrives in May to gently shear the alpacas.

- Once the fiber is removed from the alpaca the prime blanket (top quality fiber) goes into its own bag based on animal and it is labeled.

- The seconds and thirds get segregated so they can be made into secondary products. This allows us to maximize the fiber used and make the most of our annual clip (fiber harvest).

- A professional sorter arrives to our farm to review the raw fiber, grade it for softness, and separate out the best fiber from the prime blanket. This is again done by alpaca, so nothing gets commingled and contaminated.

- The fiber is grouped by color so we can make natural colors where possible and reduce the need for dying.

- The raw fiber is sent out to get professionally washed.

- Once washed, the fiber will go to a mill to get converted into roving and then spun into sock yarn. At this point we need to mix something with the alpaca so it will run through the sock machine. This could be acrylic or merino wool, and we base this decision on the end use sock.

- The yarn will return to our farm where it is then combined with other materials to be made into socks. We need to mix in nylon so the socks are durable, and they can be thrown in the washing machine by buyers. We know people don’t want to hand wash their socks.

- As the socks come off the machine my husband Jason will review them for quality.

- Damaged socks will get set aside to be discarded or made into a secondary product like a sock stuffed animal. This is my mother-in-law’s current quest, and we’ve told her to find the stuffed animals good homes who need free toys. She loved this idea, and we love her for wanting to help others.

- Socks that pass through the quality check will be washed in a washing machine, they will air dry, and then we’ll review them again for quality.

- Socks that pass through the final quality check will be labeled by me for sale.

All of this is done with sustainability in mind:

- The shearing team does travel from Montana to Michigan, but that is so we can have the best care for our alpacas. This is super important to me because our alpacas are like my pets. I’ll get on the mat with them during shearing and stay with them the entire time to help reduce any stress. I equate it to taking 50 toddlers to the dentist for a cleaning. It isn’t painful, but it can be intimidating. I want to reduce that when possible. The shearing team hates it, but they tolerate me because they know this is nonnegotiable.

- Our sorter is a local Michigan mill owner, so we keep travel reduced.

- We're currently working on training a Northern Michigan mill to spin our fiber so we can further reduce movement and the carbon footprint.

- We knit, QC, wash, and label our own socks on the farm which further reduces movement and waste.

The next time you put on a pair of socks, think about their journey. It is honestly so much more than you’d ever imagine.

Owning an alpaca farm, running our store, and purchasing our sock machine has given me have new respect for the production process and the clothing I wear. It’s also been an amazing adventure that I feel fortunate to experience. When we decided to leave corporate life and start a farm, we never thought it would lead here. But here we are, and we are thankful.

Rebecca

I

My wife and I owned New Era Fiber. If you know of us you know we have been thru this same journey for the past 23 years. We had to stop during Covid for various reasons. I would love to talk to you about your journey.

Karl we would love to chat. I’ll send an email now.